What are common flame machine maintenance tips?

1. Why is Regular Maintenance of Flame Machines Essential?

Regular maintenance of flame machines is crucial for several reasons:

Enhanced Performance: Consistent upkeep ensures reliable operation during performances, preventing unexpected failures that could disrupt events.

Extended Equipment Lifespan: Routine maintenance prevents premature wear and tear, reducing the need for costly replacements and ensuring the longevity of your investment.

Safety Assurance: Regular checks help identify and mitigate potential hazards, ensuring a safe environment for performers and crew members.

2. What Are the Common Issues Faced by Flame Machines?

Flame machines may encounter various issues, including:

Clogged Nozzles: Accumulation of debris can obstruct the flow of fuel, leading to inconsistent flame effects.

Electrical Malfunctions: Faulty wiring or components can disrupt the machine's operation, potentially causing complete failure.

Fluid Leaks: Improper storage or handling can result in leaks, posing safety risks and affecting performance quality.

3. How Should Flame Machines Be Cleaned After Use?

Cleaning flame machines involves several key steps:

Power Down and Cool Down: Always turn off the machine and allow it to cool completely before cleaning to prevent burns and ensure safety.

Disassemble Components: Carefully remove parts such as nozzles and fuel reservoirs for thorough cleaning, ensuring all components are free from residue.

Clean Nozzles and Fuel Lines: Use appropriate cleaning solutions to remove any residue or blockages, ensuring unobstructed fuel flow.

Inspect and Clean Electrical Components: Ensure all electrical connections are dry and free from corrosion to maintain optimal performance.

Reassemble and Test: After cleaning, reassemble the machine and perform a test run to confirm proper operation before the next use.

4. How Often Should Flame Machines Be Maintained?

Maintenance frequency depends on usage:

Regular Use: Machines used frequently should undergo cleaning and inspection after every performance to maintain optimal performance.

Infrequent Use: For machines used less often, a thorough inspection and cleaning should be conducted before each use to ensure readiness.

5. What Are the Best Practices for Storing Flame Machines?

Proper storage extends the life of flame machines:

Dry Environment: Store machines in a dry place to prevent moisture-related issues that could damage components.

Temperature Control: Avoid extreme temperatures that can damage components, ensuring the machine remains in optimal condition.

Secure Storage: Ensure machines are stored securely to prevent physical damage during storage periods.

6. How Can I Troubleshoot Common Flame Machine Problems?

Troubleshooting involves:

Identifying the Issue: Observe the machine during operation to pinpoint problems, such as inconsistent flame height or ignition failures.

Consulting the Manual: Refer to the manufacturer's manual for specific troubleshooting steps tailored to your machine model.

Seeking Professional Help: If issues persist, contact a qualified technician for assistance to prevent further damage and ensure safety.

7. What Are the Safety Precautions When Maintaining Flame Machines?

Safety is paramount:

Power Off: Always disconnect the power source before maintenance to prevent accidental activation.

Use Appropriate Tools: Employ the correct tools to avoid damaging components and ensure effective maintenance.

Wear Protective Gear: Use gloves and safety glasses to protect against potential hazards during maintenance procedures.

8. How Do I Ensure Compliance with Industry Standards in Maintenance?

To comply with industry standards:

Stay Informed: Keep abreast of the latest maintenance guidelines and best practices to ensure your equipment meets current standards.

Regular Training: Ensure staff are trained in proper maintenance procedures to maintain equipment reliability and safety.

Document Maintenance Activities: Keep detailed records of all maintenance work performed to track equipment history and identify recurring issues.

Conclusion: Why Choose Siterui SFX for Your Stage Special Effects Equipment?

Siterui SFX stands out in the industry for several reasons:

Quality Assurance: Offers high-quality equipment designed for durability and performance, ensuring long-term reliability.

Expert Support: Provides comprehensive maintenance services to keep your equipment in optimal condition, enhancing performance and safety.

Customer Satisfaction: Committed to delivering exceptional service and support to clients, ensuring a seamless experience from purchase to maintenance.

By adhering to these maintenance practices and choosing Siterui SFX, you can ensure your flame machines operate efficiently, enhancing the visual impact of your stage productions.

**

Siterui SFX — October 23, 2025 — Comprehensive Guide to Cleaning and Maintaining Spark Machines in Stage Special Effects

MOKA SFX — February 3, 2024 — Flame Machine: Lighter Cleaning and Maintenance

AnyCaseGear — November 13, 2025 — Everything You Need to Know About Renting a Stage Flame Machine

essential-maintenance-tips-for-stage-flame-machines

Essential Maintenance Tips for Stage Flame Machines

Ensure optimal performance and safety of your stage flame machine with these expert maintenance tips, including cleaning procedures, fuel selection, and safety precautions.

Top 10 Cold Spark Machines for 2026: A Deep Dive into Performance, Powder Life, and Durability

How to Choose a Snow Machine: The Definitive Checklist to Avoid Costly Mistakes (2026 Guide)

Fog Machines Explained: Technology, Control Systems, and Modern Stage Applications

Haze Machines Explained: The Definitive 2026+ Guide to Effects, Selection & Future Innovations

Recommended for you

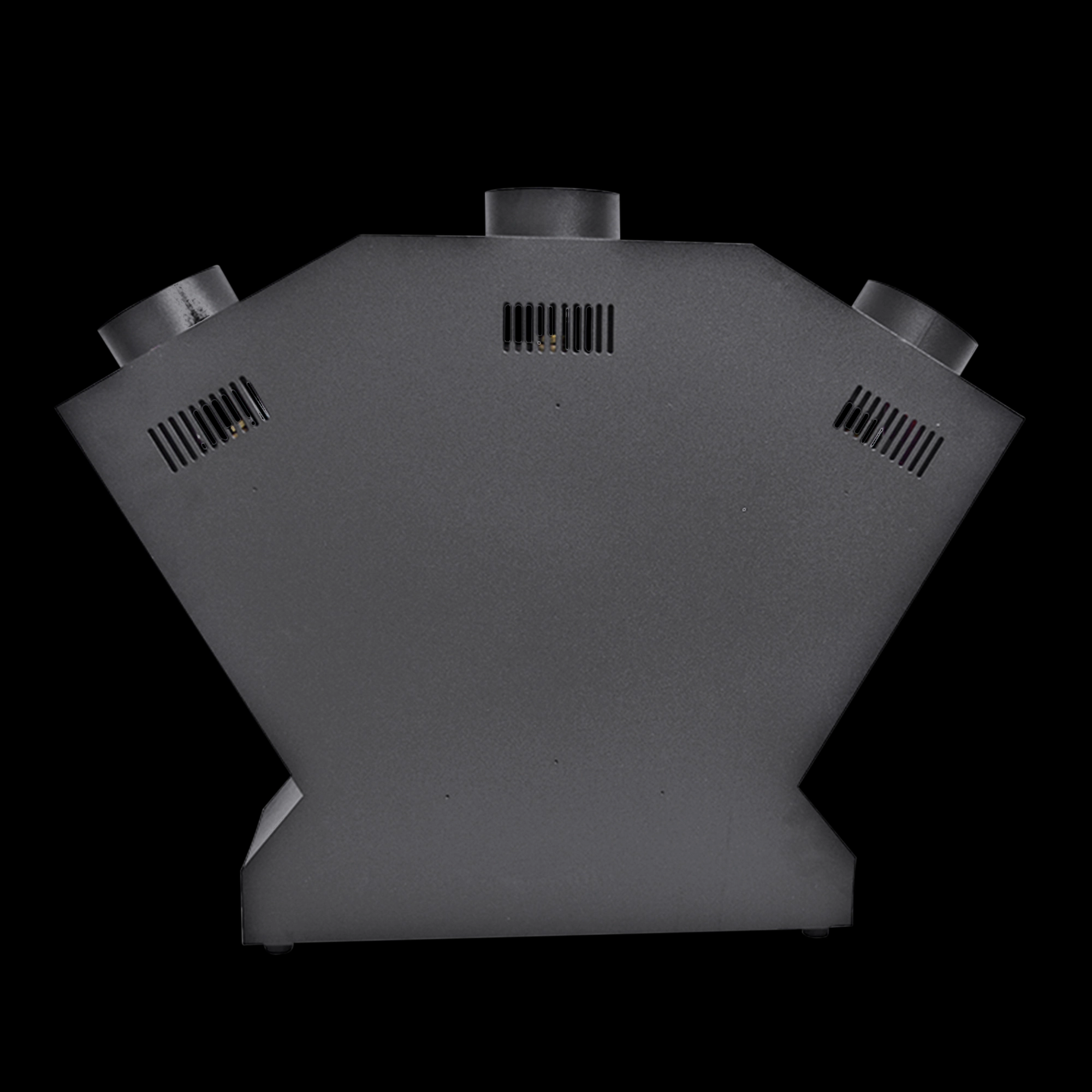

The Siterui SFX S180 Outdoor Shaking Head Fire Machine delivers dynamic flame effects for unforgettable outdoor events. Designed for durability and high performance, this fire machine enhances any show with realistic fire visuals. Perfect for professional stage and event use.

Stay Informed or Connect with Us

Have questions about our latest news or updates?

Reach out to us—we're here to provide more insights or media support.

© 2025 Siterui SFX All Rights Reserved.

Scan QR Code

Scan QR Code

Whatsapp: +8618922324800

siteruisfx_stage_equipment

Siterui

SITERUI-SFX

STRlighting

@siterui.sfx