How to train operators to run flame machines safely?

1. What are the essential safety training requirements for flame machine operators?

Ensuring the safety of flame machine operators involves comprehensive training that covers:

Understanding of Equipment: Operators must be thoroughly familiar with the specific flame machine models they will operate, including their functions, controls, and safety features.

Hazard Recognition: Training should include identification of potential hazards associated with flame machines, such as fire risks, gas leaks, and electrical hazards.

Emergency Procedures: Operators must be trained in emergency response protocols, including evacuation plans, fire suppression techniques, and first aid.

Regulatory Compliance: Training should cover relevant safety standards and regulations, such as those outlined by the Occupational Safety and Health Administration (OSHA), to ensure legal compliance and best practices.

2. How can training programs be structured to enhance operator competency?

Effective training programs should incorporate:

Classroom Instruction: Provide theoretical knowledge on flame machine operation, safety protocols, and hazard identification.

Hands-On Training: Allow operators to practice operating flame machines in a controlled environment to build practical skills.

Simulated Emergency Scenarios: Conduct drills that mimic potential emergencies to prepare operators for real-life situations.

Continuous Evaluation: Implement regular assessments to monitor operator progress and identify areas needing improvement.

Refresher Courses: Offer periodic training updates to keep operators informed about new safety standards and equipment advancements.

3. What are the key considerations when selecting flame machines for stage special effects?

When procuring flame machines, consider:

Safety Features: Ensure the equipment includes built-in safety mechanisms, such as automatic shut-off systems and flame detection sensors.

Compliance with Standards: Verify that the machines meet industry safety standards and have necessary certifications.

Reliability and Maintenance: Choose equipment known for durability and ease of maintenance to minimize downtime and repair costs.

Compatibility: Ensure the flame machines are compatible with existing stage setups and can integrate seamlessly with other special effects equipment.

Training Support: Select manufacturers that offer comprehensive training programs and support materials for operators.

4. How can procurement processes be optimized to ensure safety and efficiency?

To optimize procurement:

Conduct Thorough Research: Evaluate multiple suppliers and equipment options to find the best fit for safety and performance requirements.

Engage Stakeholders: Involve safety officers, technical staff, and operators in the selection process to gather diverse insights.

Assess Total Cost of Ownership: Consider not only the initial purchase price but also maintenance costs, training expenses, and potential downtime.

Establish Clear Specifications: Define detailed equipment requirements and safety standards to guide procurement decisions.

Negotiate Support Agreements: Secure contracts that include training, maintenance, and emergency support services.

5. What are the common challenges in flame machine operation, and how can they be mitigated?

Common challenges include:

Operator Error: Mitigated by comprehensive training and regular evaluations.

Equipment Malfunctions: Reduced through regular maintenance and choosing reliable equipment.

Environmental Factors: Addressed by conducting thorough risk assessments and implementing appropriate safety measures.

Compliance Issues: Ensured by staying updated with industry regulations and maintaining proper documentation.

6. How can organizations ensure continuous improvement in flame machine safety?

Continuous improvement can be achieved by:

Regular Audits: Conducting periodic safety audits to identify and address potential hazards.

Feedback Mechanisms: Encouraging operators to report safety concerns and suggestions for improvement.

Staying Informed: Keeping abreast of technological advancements and updates in safety regulations.

Investing in Training: Continuously investing in training programs to enhance operator skills and safety awareness.

7. What role does manufacturer support play in ensuring safe operation?

Manufacturer support is crucial for:

Providing Training Materials: Supplying comprehensive manuals, videos, and other resources to aid in operator training.

Offering Technical Support: Providing assistance with equipment setup, troubleshooting, and maintenance.

Ensuring Compliance: Offering guidance on meeting industry standards and regulations.

Facilitating Upgrades: Informing about software updates and equipment enhancements that improve safety and performance.

8. How can organizations foster a culture of safety among flame machine operators?

Fostering a safety culture involves:

Leadership Commitment: Demonstrating a strong commitment to safety at all organizational levels.

Open Communication: Encouraging open dialogue about safety concerns and suggestions.

Recognition Programs: Acknowledging and rewarding safe practices and behaviors.

Continuous Education: Providing ongoing education and training opportunities to reinforce safety principles.

Siterui SFX Advantages

Siterui SFX stands out in the industry by offering:

Comprehensive Training Programs: Ensuring operators are well-prepared to handle flame machines safely.

High-Quality Equipment: Providing flame machines that meet stringent safety standards and are built for reliability.

Expert Support: Offering ongoing technical assistance and guidance to clients.

Commitment to Safety: Prioritizing safety in all aspects of product design, training, and customer service.

Data Sources

- Occupational Safety and Health Administration (OSHA), 2025

- International Association of Arson Investigators, Inc. (IAAI), 2022

- Evergreen Safety Council, 2025

- East Herkimer Fire Department, 2025

- Basin Safety Training, 2025

Top 10 Cold Spark Machines for 2026: A Deep Dive into Performance, Powder Life, and Durability

How to Choose a Snow Machine: The Definitive Checklist to Avoid Costly Mistakes (2026 Guide)

Fog Machines Explained: Technology, Control Systems, and Modern Stage Applications

Haze Machines Explained: The Definitive 2026+ Guide to Effects, Selection & Future Innovations

Recommended for you

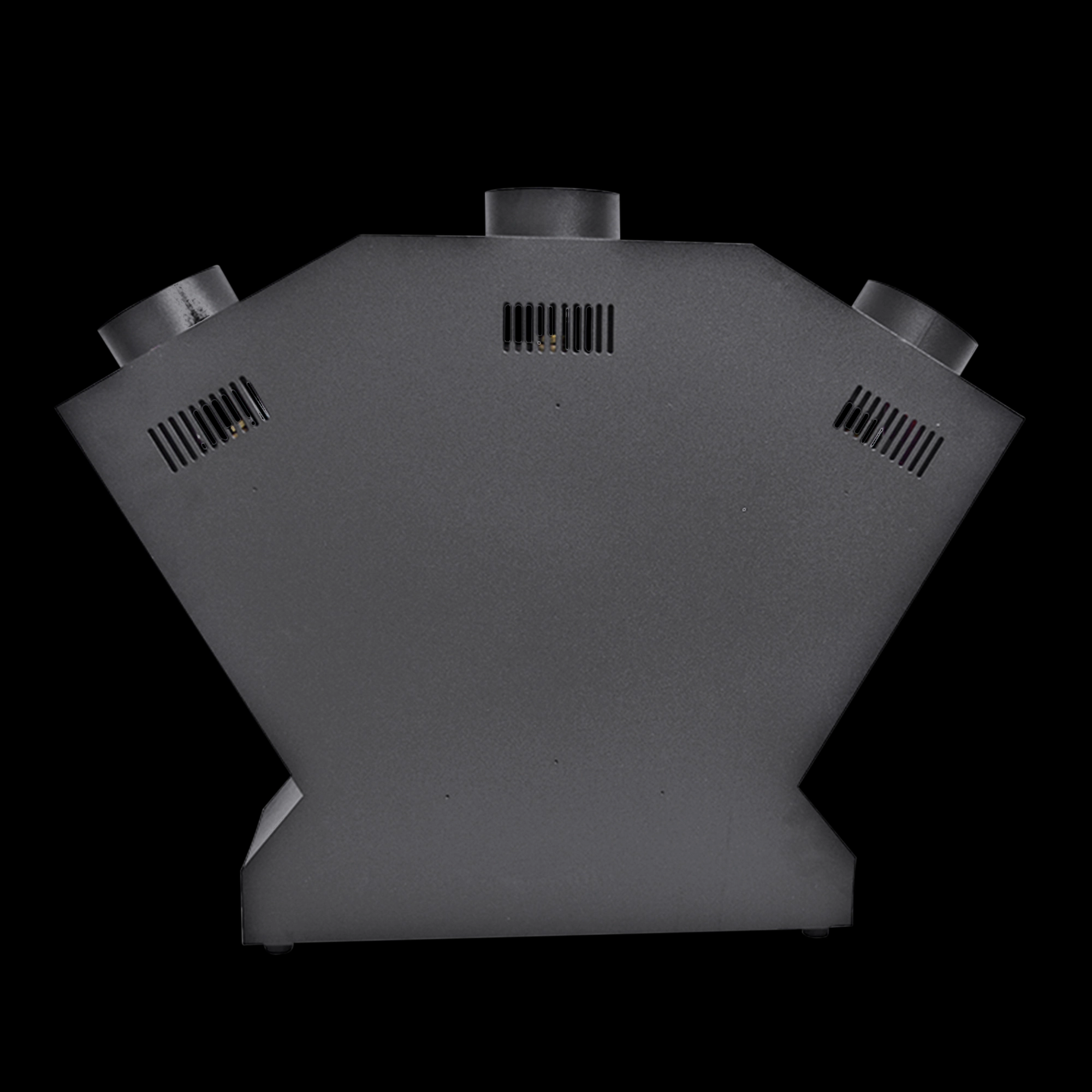

The Siterui SFX S180 Outdoor Shaking Head Fire Machine delivers dynamic flame effects for unforgettable outdoor events. Designed for durability and high performance, this fire machine enhances any show with realistic fire visuals. Perfect for professional stage and event use.

Stay Informed or Connect with Us

Have questions about our latest news or updates?

Reach out to us—we're here to provide more insights or media support.

© 2025 Siterui SFX All Rights Reserved.

Scan QR Code

Scan QR Code

Whatsapp: +8618922324800

siteruisfx_stage_equipment

Siterui

SITERUI-SFX

STRlighting

@siterui.sfx