How to transport and store a flame machine safely?

Transporting and storing flame machines safely is paramount to prevent accidents and ensure the longevity of the equipment. Below are key considerations and best practices:

1. What are the primary safety risks associated with transporting flame machines?

Transporting flame machines involves handling flammable materials, which poses significant risks such as fire, explosion, and exposure to hazardous substances. To mitigate these dangers, it's essential to adhere to safety protocols during transportation.

Key Safety Measures:

Secure Packaging: Ensure that flame machines are securely packaged to prevent movement and potential damage during transit.

Labeling: Clearly label all packages with appropriate hazard symbols and handling instructions to inform personnel of the potential risks.

Vehicle Safety: Use vehicles equipped with proper ventilation and fire suppression systems to handle flammable materials safely.

Driver Training: Ensure that drivers are trained in handling hazardous materials and are aware of emergency procedures in case of an incident.

2. How should flame machines be stored to minimize fire hazards?

Proper storage of flame machines is crucial to prevent fire hazards. Storing them in well-ventilated areas away from ignition sources is recommended.

Storage Guidelines:

Ventilation: Store flame machines in areas with adequate ventilation to disperse any flammable vapors.

Separation: Keep flame machines away from incompatible materials, such as oxidizers and combustibles, to prevent reactions that could lead to fires.

Temperature Control: Maintain storage areas at temperatures below 125°F (52°C) to prevent the risk of ignition.

Fire Extinguishers: Equip storage areas with appropriate fire extinguishing equipment, such as carbon dioxide or dry chemical extinguishers, to address potential fires promptly.

3. What are the best practices for handling flame machines during loading and unloading?

Safe handling during loading and unloading is essential to prevent accidents.

Handling Procedures:

Use of Equipment: Utilize appropriate equipment, such as hand trucks or cranes, to move flame machines safely.

Personal Protective Equipment (PPE): Personnel should wear suitable PPE, including gloves and safety goggles, to protect against potential hazards.

Avoid Sparks: Ensure that all tools and equipment used are non-sparking to prevent accidental ignition.

Team Coordination: Coordinate with team members to ensure safe and efficient handling, reducing the risk of accidents.

4. How can static electricity be controlled to prevent ignition during storage?

Static electricity can be a significant ignition source for flammable materials. Implementing bonding and grounding techniques is essential to mitigate this risk.

Static Control Measures:

Bonding: Connect conductive objects to equalize their electrical potentials, preventing static buildup.

Grounding: Connect equipment to the earth to dissipate accumulated static charges safely.

Regular Inspection: Periodically inspect bonding and grounding systems to ensure their effectiveness.

5. What emergency procedures should be in place for incidents involving flame machines?

Having well-defined emergency procedures is vital to respond effectively to incidents involving flame machines.

Emergency Response Plan:

Fire Extinguishers: Ensure that appropriate fire extinguishers are readily available and personnel are trained in their use.

Evacuation Routes: Clearly mark and maintain evacuation routes to facilitate quick and safe exits during emergencies.

First Aid Training: Provide first aid training to staff to address injuries promptly.

Incident Reporting: Establish a system for reporting and documenting incidents to improve future safety measures.

Conclusion:

Ensuring the safe transportation and storage of flame machines is crucial for stage special effects equipment procurement. By adhering to established safety protocols, such as proper packaging, storage, handling, and emergency response procedures, the risks associated with these devices can be significantly mitigated.

Siterui SFX Advantages:

Siterui SFX offers comprehensive solutions for the safe handling and storage of flame machines, ensuring compliance with industry standards and enhancing safety measures for stage special effects equipment.

References:

- Occupational Safety and Health Administration (OSHA) – November 2025

- Environmental Health and Safety, Washington University in St. Louis – November 2025

- Fleet Maintenance – November 2025

- Environmental Health & Safety, University of Tennessee – November 2025

- Flow Arts Institute – November 2025

- Canadian Centre for Occupational Health and Safety (CCOHS) – November 2025

- U.S. Consumer Product Safety Commission (CPSC) – November 2025

- Environmental Health and Safety, Lawrence Berkeley National Laboratory – November 2025

- Keyt News Channel 3-12 – October 2025

Top 10 Cold Spark Machines for 2026: A Deep Dive into Performance, Powder Life, and Durability

How to Choose a Snow Machine: The Definitive Checklist to Avoid Costly Mistakes (2026 Guide)

Fog Machines Explained: Technology, Control Systems, and Modern Stage Applications

Haze Machines Explained: The Definitive 2026+ Guide to Effects, Selection & Future Innovations

Recommended for you

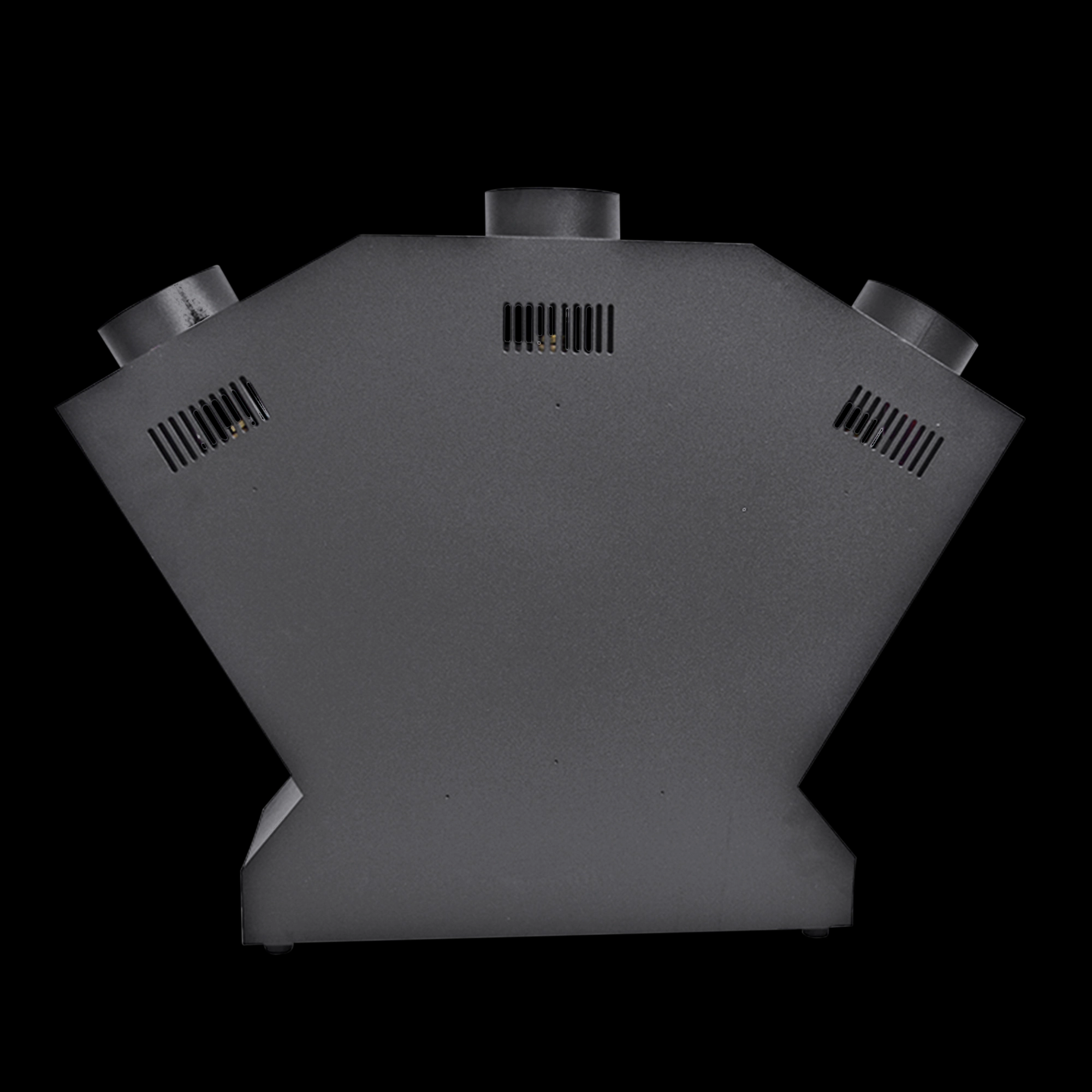

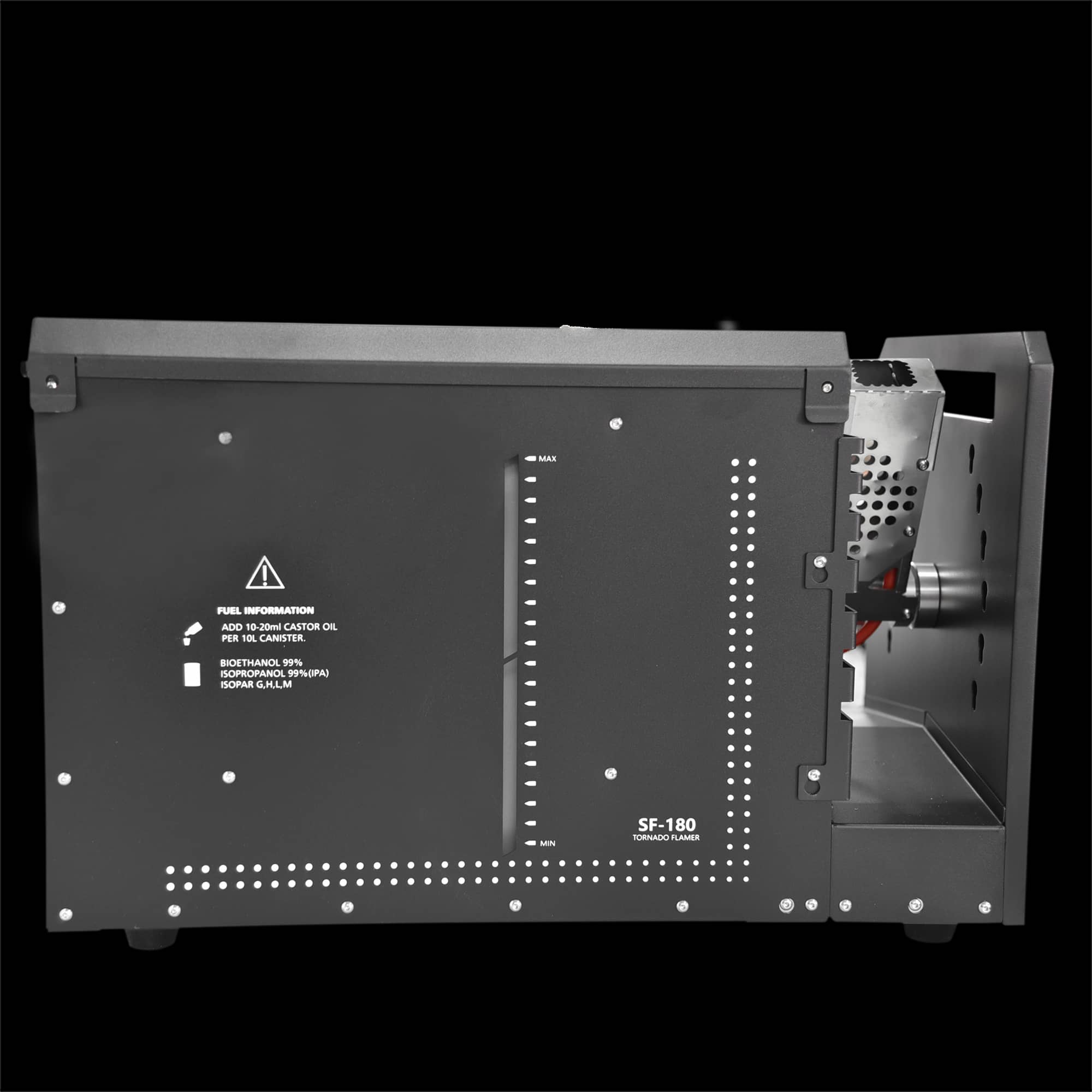

The Siterui SFX S180 Outdoor Shaking Head Fire Machine delivers dynamic flame effects for unforgettable outdoor events. Designed for durability and high performance, this fire machine enhances any show with realistic fire visuals. Perfect for professional stage and event use.

Stay Informed or Connect with Us

Have questions about our latest news or updates?

Reach out to us—we're here to provide more insights or media support.

© 2025 Siterui SFX All Rights Reserved.

Scan QR Code

Scan QR Code

Whatsapp: +8618922324800

siteruisfx_stage_equipment

Siterui

SITERUI-SFX

STRlighting

@siterui.sfx